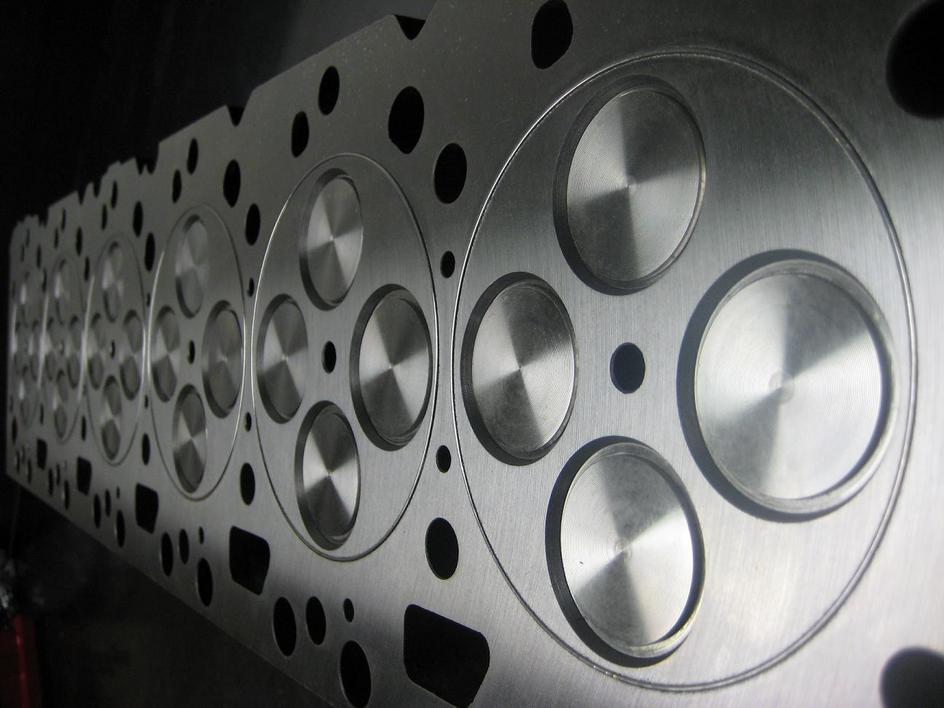

Valve Grinding to OEM specifications is one of the most important machining operations performed to insure that your diesel engine is running to its potential. Each cylinder head is disassembled and cleaned, guides, valves, and springs all checked for reuse and replaced if not up to new engine standards. This is an ideal time to check the head for cracks, cracked seats, gasket surface irregularities, corrosion, and warpage. Also corrected during the process is setting accurate valve recession to insure correct valve geometry and displacement for each cylinder. This is especially critical on diesel engines. Each valve is refaced and stem is checked for wear or defects. Any necessary guide work is performed, resurfacing if requested or required, and then the seats are all cut with 3 angle carbide cutters with proper width and angle configurations, and then polish ground and hand lapped for 100% sealing. Final cleaning is then performed, and new valve seals are installed as the head is assembled. While assembling, all spring heights are checked and corrected as needed. The head is then painted and ready for installation.